innovative Technology

Battery to power robotic technology

DSTEM patent-pending shaft cell and pack architectures synchronize battery performance with thermal safety for robust power application.

✓ ECONOMical manufacturing

✓ Energy efficiency

✓ easy expanding

Battery cell design 2.0

- What are changing in the end-user market and the pain points of the cell industry

- From a single cell or a handful of cells, typically used in consumer electronic devices, to a collection of cells with unit energy consumption at 1kWh and above

- An individual cell in a pack to electrify a system contains 10X or 100X more energy than that of 18650, and is much more economy in manufacturing and packing

- The heating and safety of big cells are as critical as their electrochemical functions to drive a system, and takes a big portion of the daily operation costs

- Cell manufacturing lags far behind the market demands, characteristic of high costs and slow paces in setting and scaling production line up with wild cell forms

- What unchanged is the demanding of high cost-performance ratio of cells

- DSTEM’s philosophy of Battery cell design 2.0

- DSTEM Cells are a structural and functional module of a pack to achieve 1 + 1 > 2 synergies in pack performance, durability, efficiency, and safety

- DSTEM Cells are designed on the end-user’s usage scenarios with high pack flexibility in the field

- DSTEM Cells and Packs are characteristic of collective energy-power balance and heat-cooling efficiency

- DSTEM Cells and Packs root on an innovative cell form, supporting all current and in-developing cell chemistry and cell physics in the market

- DSTEM technology supports Global resource and Local manufacturing at accelerate pace to handle the supply chain logistic challenging

- DSTEM technology supports Easy packing and Easy disassembly for recycling and throughout lifecycle management

How to improve the Tesla 4680-type cell performance and manufacturing

DSTEM shaft cell and pack architectures empower customers to use them in all-weather, all-terrain electrified power applications, ranging from data center power plants, mobile energy grids, to powertrain fleets across the sky, the sea, or the land, with high standard safety and reliability.

01

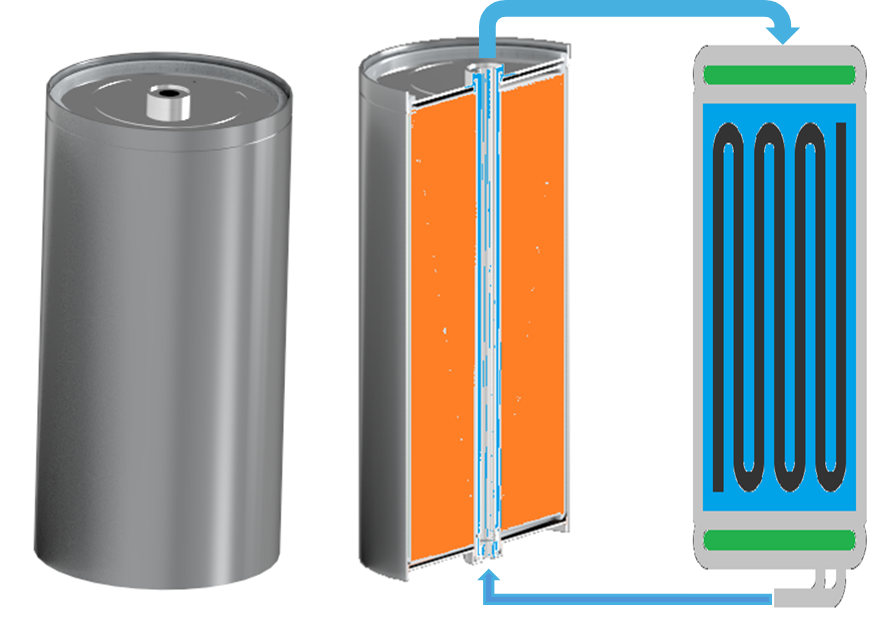

shaft cell architecture

USA patent pending (US63/739679): Shaft cell and methods of manufacturing thereof

- removing top cap and parts to reduce costs

- face-to-face connection to promote electric and thermal conductions

- thermal uniform from inner core to outer peripheral to enhance cell safety and longevity

02

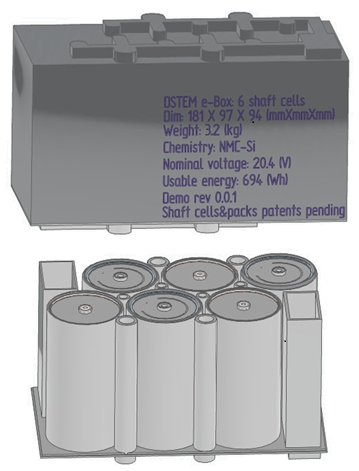

shaft cell pack architecture

USA patent pending (US63/762808): Shaft cell pack and methods of manufacturing thereof

- hierarchical structure, functional, and protection from unit cell to cell cluster and running up to cell network

- protocols binding cell chemistry with thermal entropy minimization

- unique terminal busbar-cooling and fireproof design

03

shaft cell and pack manufacturing

Consistent and competitive manufacturing of cell and pack at the same level

- reducing costs in parts and inventory

- rapid equipment and assembling scaling-up for flexible footprints of cell and pack

- high yield assembling and formation in mass productions of cell and pack

- short lead time to meet end-user’s “Can-be-assembled” application in the field and on the flying